Get in touch for a Quote - Contact us

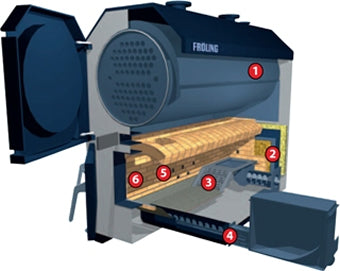

Wood chip boiler for automatic burning of: fuel as per EN ISO 17225

Fire tube - smoke pipe boiler, in three-flue design

SPS 4000 control system:

Used to control the drive units of the boiler system, upgradeable modular design

Stoker unit not included with boiler

(available in a choice of three different models)

|

Performance data LM KOM |

|

750 |

1000 |

1500 |

|

Nominal heat output |

kW |

750 |

980 |

1500 |

|

Output range |

kW |

225 - 750 |

295 - 980 |

450 - 1500 |

|

Electrical connection 400V / 50Hz / according wiring diagram |

||||

|

Weight combustion chamber / heat exchanger kg |

3620 / 3500 |

4900 / 4600 |

7600 / 8200 |

|

|

Weight refractory material kg |

4320 |

5400 |

7500 |

|

|

Total weight incl. fittings kg |

11440 |

14900 |

23300 |

|

|

Water capacity liter |

1840 |

2390 |

4240 |

|

|

Water side resistance dT = 20 K mbar |

15 |

27 |

-- |

|

|

Minimum boiler return temperature °C |

|

65 |

|

|

|

Max. permitted operating temperature °C |

|

90 |

|

|

|

Permitted operating pressure bar |

4 |

6 |

6 |

|

|

Technical data LM KOM |

750 |

1000 |

1500 |

|

|

H Height, boiler |

3600 |

3855 |

4360 |

|

|

H1 Height, flow/return connection |

3660 |

3915 |

3935 |

|

|

H2 Height, Stoker unit |

1220 |

1200 |

255 |

|

|

H3 Height, flue gas pipe connection |

3250 |

3570 |

1850 |

|

|

B Total width including fittings |

1630 |

1630 |

1290 |

|

|

B1 Length, stoker unit |

1290 |

1290 |

1295 |

|

|

B2 Width, ash container (optional) |

1295 |

1275 |

4585 |

|

|

L Boiler length |

3075 |

3675 |

4660 |

|

|

L1 Length, boiler incl. reversing chamber door and stoker unit |

2710 |

3380 |

1500 |

|

|

L2 Length, flue gas collection box |

255 |

255 |

4200 |

|

|

Boiler data for sizing the flue gas system |

750 |

1000 |

1500 |

|

|

Flue gas temperature NL / PL °C |

220 / 160 |

220 / 160 |

220 / 1600 |

|

|

Flue gas mass flow NL / PL kg/s |

1,017 |

1,329 |

4428 |

|

|

Minimum feed pressure NL / PL mbar |

0,05 / 0,02 |

0,05 / 0,02 |

0,05 / 0,02 |

|

|

Flue gas pipe diameter |

400 |

450 |

500 |

|

|

|

|

|

||

All information in mm!