Viessmann Vitodens 200 B2HA 3 x 150kW in Series 150 kW - B2HA182

Please call to check availability before ordering Live Chat / 01985 850982

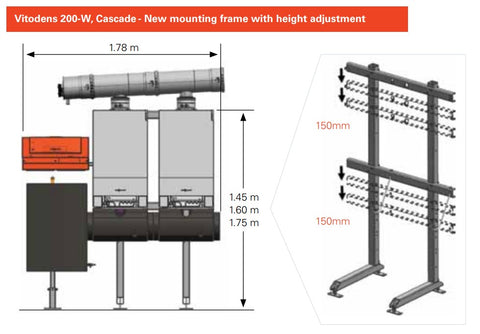

Now 30% smaller than the previous cascade configuration, it is perfect for plant rooms with lower footprints or with a small headroom, as the boiler height can be adjusted on the frame. Suitable for row, block or even corner installations, the compact cascade can be wall mounted or simply fitted with a free-standing frame for 2,3,4,5 or 6 boiler units at a time. This can deliver a maximum output of 594 kW with a 6 boiler cascade

Addition Accessories required

Adaptor flanges DN 100 to R 2

Can be used for total heating outputs of up to 200 kW in conjunction

with a cascade module adaptor

Part no. ZK02629

----------------------------

Pipe bends 90°

For corner installation, multi boiler system

Part no. ZK02630

Comprising:

■ 2 pipe bends

■ Thermal insulation

■ Support

----------------------------

Condensate collectors

Comprising:

■ Condensate collector with tee and brackets

■ Drain hose for connecting to the drainage system

■ Connection hose for condensate drain from trap

■ Connection hose for draining the safety valve for each boiler

- Two-boiler system: Part no. ZK02631

- Three-boiler system: Part no. ZK02632

- Four-boiler system: Part no. ZK02633 (block or inline formation)

- Five-boiler system: Part no. ZK02634

- Six-boiler system: Part no. ZK02635 (block or inline formation)

----------------------------

A - Flue gas header, B - Terminal with trap

Flue gas cascades (positive pressure)

Comprising:

■ Flue gas header

■ Terminal with condensate drain and trap

Two-boiler system in inline formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00675

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00676

Three-boiler system in inline formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00678

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00679

Four-boiler system in inline formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00681

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00682

Five-boiler system in inline formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK02636

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK02637

Six-boiler system in inline formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00684

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00685

Four-boiler system in block formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00689

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00690

Six-boiler system in block formation

– For Vitodens 200-W, 49 and 60 kW: Part no. ZK00691

– For Vitodens 200-W, 69 to 99 kW: Part no. ZK00692

For further specifications on the flue gas cascades, see the technical guide to Vitodens flue systems.

----------------------------

Note

When installing a flue gas cascade, a second flue gas back draught

safety device for each boiler must be added to the order!

Back draught safety device for Vitodens 49 kW

Comprising a back draught safety device DN 80 with coding card.

For vertical installation in the continuing flue pipe, directly downstream of the boiler.

Must be added to the order for every boiler in the flue gas cascade:

Part no. ZK07169

Back draught safety device for Vitodens 60 kW

Comprising a back draught safety device DN 80 with coding card.

For vertical installation in the continuing flue pipe, directly downstream of the boiler.

Must be added to the order for every boiler in the flue gas cascade:

Part no. ZK07170

Back draught safety device for Vitodens 80 kW

Comprising a back draught safety device DN 110 with coding card.

For vertical installation in the continuing flue pipe, directly downstream of the boiler.

Must be added to the order for every boiler in the flue gas cascade:

Part no. ZK07171

Back draught safety device for Vitodens 99 kW

Comprising a back draught safety device DN 110 with coding card.

For vertical installation in the continuing flue pipe, directly downstream of the boiler.

Must be added to the order for every boiler in the flue gas cascade:

Part no. ZK07172

----------------------------

Design information

A Cascade module adaptor

B Low loss header

C Air vent valve

D Sensor well for flow temperature sensor

E Boiler drain & fill valve

F High efficiency circulation pump

G Boiler drain & fill valve

H Safety valve

K Drain

L Vitotronic 300-K (can be fitted either to the left or the right)

The total length of all BUS cables (on site) should not exceed

50 m.

HR Heating water return

HV Heating water flow

Vitodens 200-W compact cascade system

- Flue gas cascade

- Vitodens 200-W gas condensing boiler

- Heating circuit connection set

- Cascade frame or wall bracket

- Low loss header

Cascade Specifications

- Maximum Install Height With frame and gas header: 2 metres Without frame: 1.8 metres

- Minimum Install Height With frame and gas header 1.7 metres Without frame: 1.5 metres