MasterTherm BoxAir Inverter - Air to Water Air Source Heat Pump

Air to Water Air Source Heat Pump

The MasterTherm BoxAir Inverter is a compact and quiet air source heat pump that utilizes inverter technology to efficiently modulate its output between 30-100%. This not only provides an exceptional level of operational efficiency, but also helps to prolong the lifespan of the system by avoiding continuous start and stop cycling. In addition, the BoxAir offers advanced control for heating circuits and weather compensation, and can even be integrated with solar technology to create a comprehensive and efficient heating solution.

Features

- Outdoor compact

- Use for heating and cooling

- The temperature of heating water to 60 °C

- Temperatures range from +35 °C to -20 °C

- Very easy installation, quiet operation

- Control up to 6 heating circuits

Standard equipment

- Graphic terminal PGD

- Variable output Inverter Compressor

- New low-noise fan

- Equitherm control system MaR

- Built-in immersion heater and circulation pump

- Electronically controlled coolant injection

Contact us for a quote : Live Chat / 01985 850982

Models Available

- BoxAir 22I

- BoxAir 26I

- BoxAir 30I

- BoxAir 37I

- BoxAir 45I

1) Performance data according to ČSN EN 14 511, in accordance with the EHPA requirements

for quality mark Q. A7W35 60 Hz - air 7 °C, water 35 °C, compressor frequency 60 Hz

2) Recommended value of el. 3x400V fuse, incl. Auxiliary integrated electric boiler. The

units 22I, 26I and 30I can also be connected to a 1x230V network with 40A"B"(22I),

resp. 50A"B"(26I, 30I).3) Design power at outdoor temperature -10 ° C according to ČSN EN 14 825.

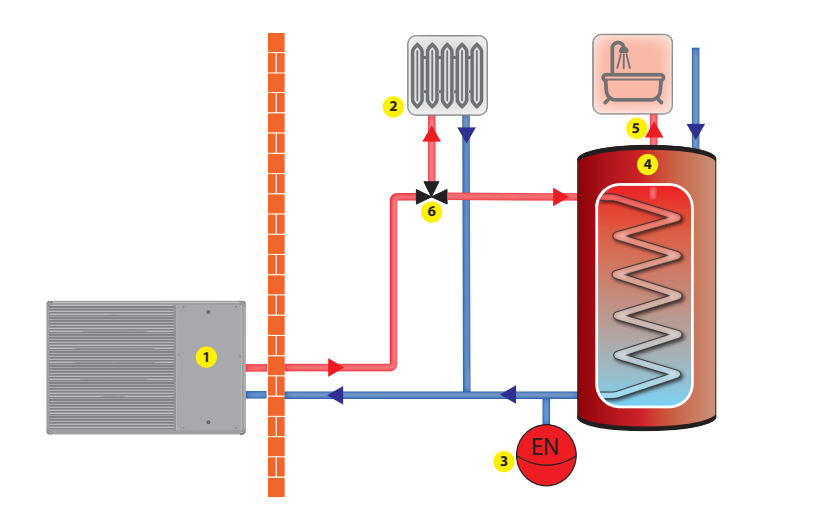

Heat pump connected directly to the heating system with 3wv for domestic hot water (dhw) preparation

1-heat pump, 2-heating system, 3-expansion vessel, 4-dhw tank with coil, 5-dhw outlet, 6-3way valve

The heat pump (1) is directly connected to heating system. Heating water temperature is controlled according to a weather compensation curve. Production of hot water is a priority over the heating system by switching the 3wv (6) to the dhw tank (4). The heat pump increases the outlet water temperature until the requested dhw temperature is achieved, once achieved the heat pump switches the 3wv back to heating operation. This type of system is ideally suited to underfloor heating systems (ufh) but also

systems with radiators with a large volume of heating water utilising our pAD room terminal. This solution limits the possibility of local zone control (independent loop ufh, thermostatic valves on radiators).

Dimensions and connections: BA30I and BA45I:

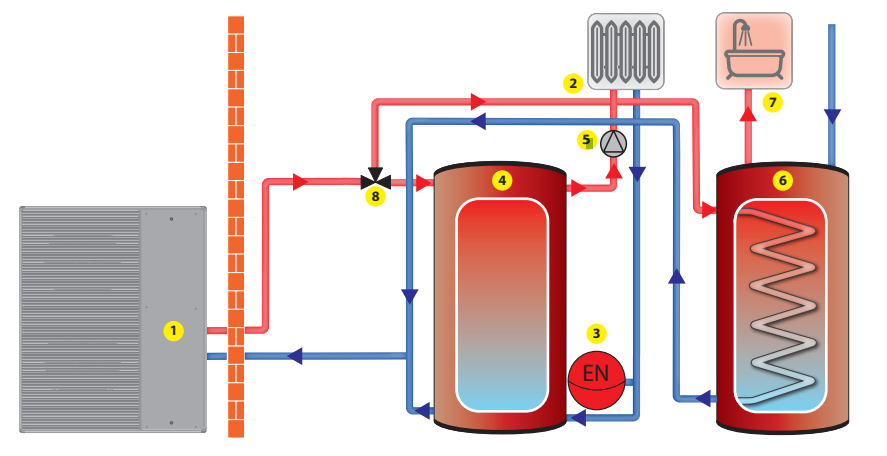

Heat pump connected to a buffer tank and 3wv to the domestic hot water cylinder (dhw)

1-heat pump, 2-heating system, 3-expansion vessel, 4-buffer tank, 5-heating circulator pump, 6-dhw tank with coil, 7- dhw outlet, 8-3way valve

Heat pump (1) connected to the heating system through a buffer tank (4) which has the function of thermal buffer and a low loss header. Heating water temperature is controlled according to a weather compensation curve. The flow to the heating system is controlled by the main heating circulation pump. Production of hot water is a priority over the heating system by switching the 3wv (8) to the dhw tank (6). The heat pump increases the outlet water temperature until the requested dhw temperature is achieved, once achieved the heat pump switches the 3wv back to heating operation. This solution is ideally suited to systems with low heat buffering capacity and systems that require independent room zone control. Additionally, this type of system has the ability to integrate a secondary source of heat into the buffer tank (4) such as a wood stove with back boiler.