Flexfiller Direct G4 - Pumpless Digital Pressurisation Technology

The Flexfiller Direct G4 is the latest in pumpless digital pressurisation technology for light commercial and residential buildings. It’s a slim, wall-mounted pumpless top-up pressurisation unit, with a top-up flow rate of up to 14 l/min depending on the mains or boosted mains, water pressure. It is designed to be connected directly to a building’s incoming water supply using the included flexible hose. It is there to fill and maintain the pressure of a heating or chilled water system without the need for a pump. The unit comes with a user-friendly controller that displays all operating and error conditions comprehensibly and conveniently. It features extensive data storage for online and offline analysis, microprocessor control, and self-learning algorithms with a graphical display. It comes with MODBUS RTU and BACnet communication protocols as standard and has its key operating parameters password protected.

Product features

- Silent, pumpless pressurisation unit.

- Fills system from empty.

- For system volumes up to 15,000 litres.

- Fluid Protection Category 4 backflow prevention.

- Onscreen service reminder (12 months).

- Colours: Grey (RAL7016) and Red (RAL3002).

- Password protected.

- Pressure setting in 0.1 bar increments.

- Flood protection (Runtime limiter and excessive activation logging).

- Volt free contact: Common alarm (N/C or N/O), fully programmable for specific alarms customisable via control unit).

- Extensive data storage for online or offline analysis.

- Advanced technology ensures the lowest power consumption, long service life and easy maintenance.

- Microprocessor control, self-learning with graphical display.

- Max. flow rate of 14 l/min.

- Connects directly to the mains (boosted) water mains, via included flexible hose (L = 400 mm).

| Type | Connections | Standby Power Consumption [W] |

Full Load Current [A] |

Weight [kg] |

Order Code |

||||

| System [mm] |

Mains Supply [mm] |

Drain (Tundish) * | |||||||

| Flexfiller Direct G4 | 15 (compression) | 15 (compression) | 3⁄4" BSP | 2 | 0.3 | 4 | 1 | 20100 | |

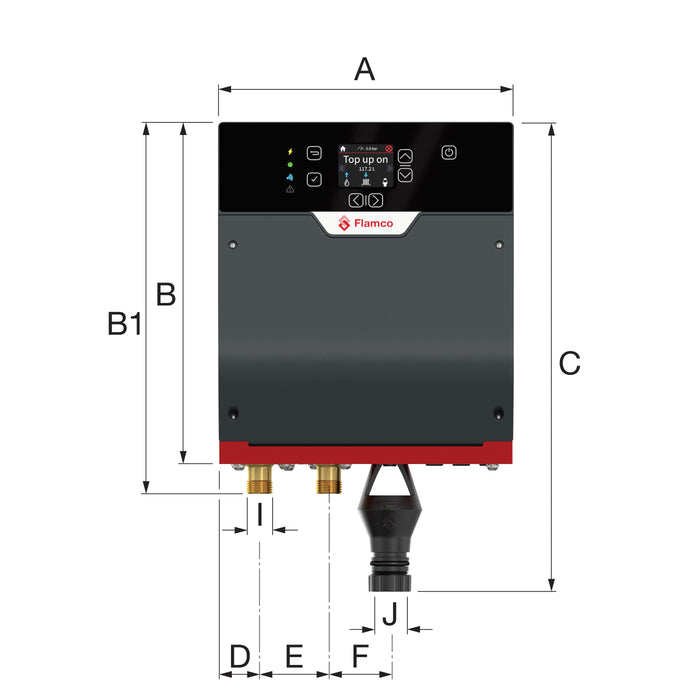

| Type | Dimensions | ||||||||||

| A [mm] |

B [mm] |

B1 [mm] |

C [mm] |

D [mm] |

E [mm] |

F [mm] |

I ["] |

J [mm] |

K [mm] |

M [mm] |

|

| Flexfiller Direct G4 | 225 | 262 | 284 | 359 | 32 | 53 | 46 | 1/2" BSP | 22 / 32 * | 141 | 30 |

Certifications and Standards Applied PED 2014/68/EU Sound Engineering Practice. IEE - Electrical Safety Guidance. EMC 2004/108/EC. BS 7074 Parts 1 to 3. Machinery Directive 2006/42/EC, UK Supply of Machinery (Safety) Regulations 2008. Electronic Components have been tested and comply with the EMC Directives, UK EMC Regulations 2016. EN 61000-6-2: Generic Standards – Immunity standard for industrial environments. EN 61000-6-3: Generic Standards – Emission standard for residential, commercial and light industrial environment. Low Voltage Directive 2014/35, Electrical Equipment (Safety) Regulations 2016. CE marked components, where applicable. WRAS approved check valve. IP44 (BS EN60529) rated controller.

Materials of construction Cabinet: Mild steel CR4 Powder Coated Drain manifold: PA66 GF30 Check-valves: POM Filter: POM Connections: In -and outlet manifold: DZR Brass Tundish: PA66 GF30 Pipework: Stainless steel braided Flexible hose / EPDM / Copper Finish: Powder coated Valves: Brass / PTFE