14270: 2 x Pellet boiler PE1 Pellet 25kW to 35kW With/WithOut condensation

by FROLING

SKU 14270

Get in touch for a Quote - Contact us

Fully automated pellet boiler with induced draft fan and modulating fuel feed. For combustion of 6mm wood pellets according EN ISO 17225, part 2: wood pellet class A1 / D06.

Control system P 3200 Touch

Microprocessor controls for optimising the combustion process through precise control of the boiler- and exhaust gas temperature, including actuators for primary and secondary air dampers, 7 ” color display for the representation of all important values and status messages with USB interface for updates; including lambdacontrol

Scope of delivery:

(2nd heating circuit possible via additional sensor)

Optional:

Control expandable to 18 heating circuits (wall enclosures) and total

8 hydraulic modules (wall housing); thereby numerous additional functions such as solar, oil / gas boilers, circulation, differential control

(e.g., water-borne chimney insert), etc. are possible. For additional equipment see connection diagrams

Advantages

Download

|

Pellet boiler in cascade operation |

Output |

Item-no. |

|

|

2 x PE1 Pellet 25 1) |

7,2-50 |

kW |

14270 |

|

2 x PE1 Pellet 30 1) |

7,2-60 |

kW |

14271 |

|

2 x PE1 Pellet 35 1) 2 x PE1 Pellet 25 with condensing heat exhanger 1) |

7,2-70 8,2-55 |

kW kW |

14272 14270BW |

|

2 x PE1 Pellet 30 with condensing heat exhanger 1) |

9,6-64 |

kW |

14271BW |

|

2 x PE1 Pellet 35 with condensing heat exhanger 1) |

11,4-76 |

kW |

14272BW |

|

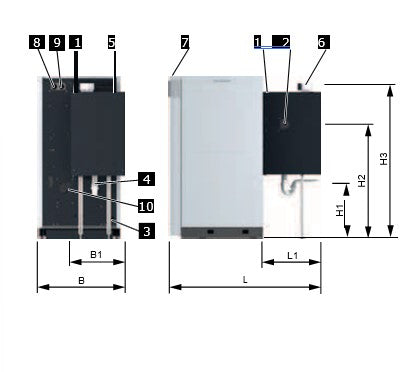

Technical data PE1 Pellet |

7 |

10 |

15 |

20 |

25 |

30 |

35 |

|

H Height of boiler |

1200 |

1200 |

1200 |

1200 |

1470 |

1470 |

1470 |

|

H1 Height of flue pipe connection |

940 |

940 |

940 |

940 |

1170 |

1170 |

1170 |

|

H2 Height, flow connection |

930 |

930 |

930 |

930 |

1160 |

1160 |

1160 |

|

H3 Height, return connection |

750 |

750 |

750 |

750 |

920 |

920 |

920 |

|

H4 Height of drainage connection |

95 |

95 |

95 |

95 |

175 |

175 |

175 |

|

H5 Height of supply air connection (for room air-independent operation) |

390 |

390 |

390 |

390 |

460 |

460 |

460 |

|

H6 Height of suction system connection |

1110 |

1110 |

1110 |

1110 |

1380 |

1380 |

1380 |

|

B Width of boiler |

650 |

650 |

750 |

750 |

750 |

750 |

750 |

|

L Length of boiler |

690 |

690 |

690 |

690 |

850 |

850 |

850 |

|

L1 Total length incl. flue gas pipe connection |

760 |

760 |

740 |

740 |

890 |

890 |

890 |

|

Technical data PE1 Pellet Condensing |

15 |

20 |

25 |

30 |

35 |

|

L Total length incl. condensing heat exchanger |

1185 |

1185 |

1385 |

1385 |

1385 |

|

L1 Length condensing heat exchanger |

495 |

495 |

535 |

535 |

535 |

|

B Total width of boiler incl. condensing heat exchanger |

800 |

800 |

800 |

800 |

800 |

|

B2 Width of condensing heat exchanger |

590 |

590 |

615 |

615 |

615 |

|

H1 Height of drainage connection |

150 - 320 |

150 - 320 |

480 - 590 |

480 - 590 |

480 - 590 |

|

H2 Height, return connection |

809 |

809 |

1045 |

1045 |

1045 |

|

H3 Height of flue pipe connection |

1175 |

1175 |

1410 |

1410 |

1410 |

All information in mm!